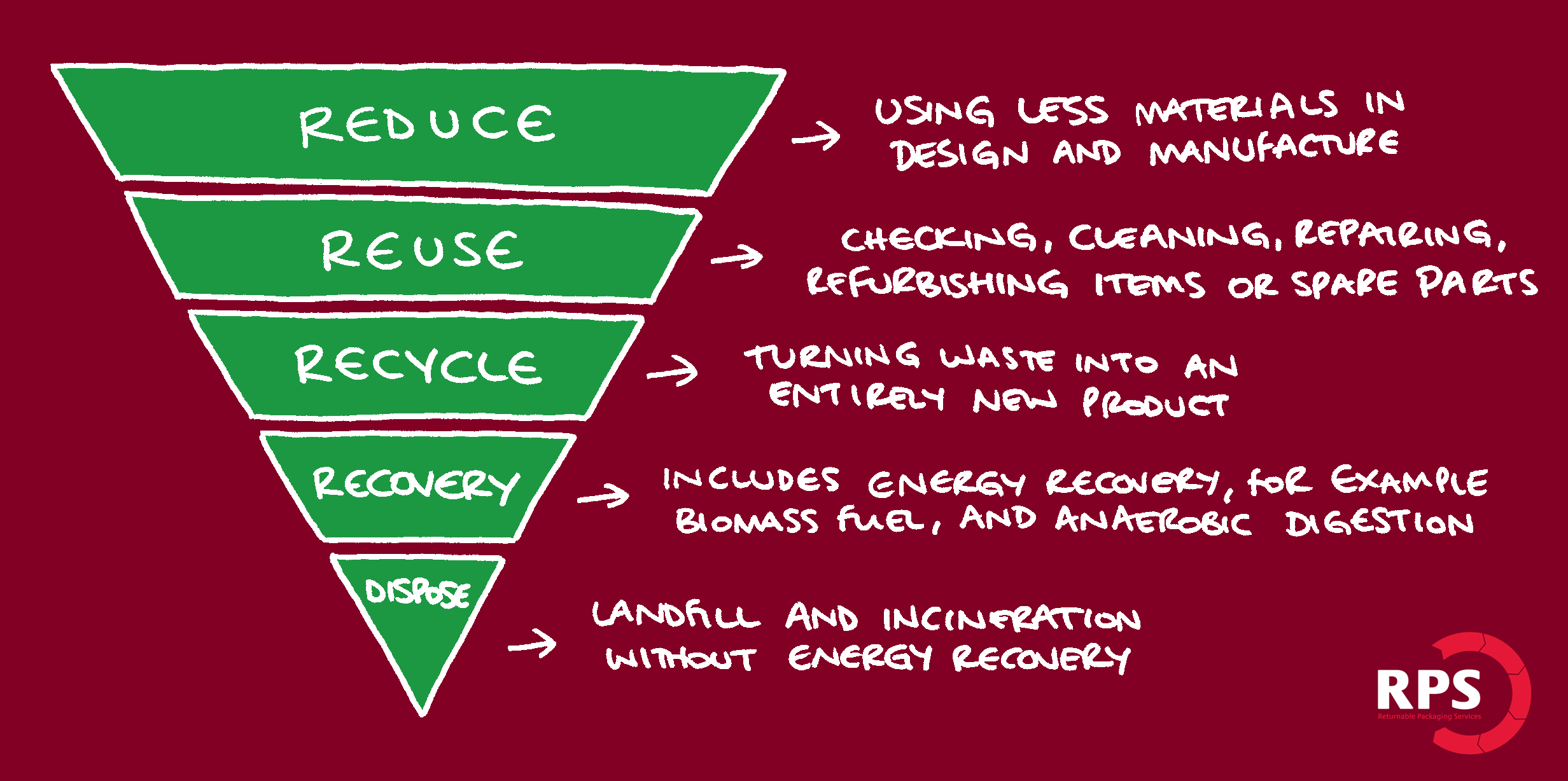

Here at RPS we’re always trying to reduce and reuse as much as possible, after all, we must practice what we preach! That’s why over the last year as part of our commitment to reduce our environmental impact within our supply chain, we’ve steadily been cutting back and focusing on our collections, deliveries and consumable purchases.

After months of hard work, we have reduced the number of deliveries from just two of our suppliers, from 93 (during 2015/16) to 65 deliveries (during 2016/17). That’s a reduction of 30%! Applying the same principles to other associates within our supply chain could help achieve similar results.

By ordering just what we need, and more importantly only when we need it, has helped us to reduce the number of trips from our suppliers. By bulking up on orders we’ve managed to reduce our carbon footprint and decrease our impact on the environment.

We’ve also taken advantage of our work within the Pallet Co-Operative, allowing us to cut the distance pallets travel to be sorted, repaired and prepared for reuse. This past year, for just two of our collection points, we’ve been able to redirect more than 90 full loads of pallets to one of our strategically place partners and reduced the number of miles travelled by 9,432!

Not only have we reduced our waste but business is booming and we’ve added some new faces to the team to help us drive our waste reduction initiatives. It just goes to show that any firm can cut its waste!

We’d love to hear how you have reduced your waste at work? Share your thoughts and what you learned by tweeting us, @RPS_Limited!